These springs absorb and store energy by resisting extension. Typically they are made from round wire and are close wound with initial tension. Applications include, balance scales, garage doors, trampolines, washing machines and general tensioning devices. Various types of ends are used to attach the extension spring to the source of the force, typically hooks or loops.

The wind can be manipulated to achieve the load requirements, but unlike a compression spring, which has zero load at zero deflection, an extension spring can have a preload at zero deflection. This built-in load, called initial tension, can be varied within limits, decreasing as the spring index increases.

There is a range of stress (and therefore force) for any spring index that can be held without problems. If the design needs an extension spring with no initial tension it should be designed with space between the coils.

Materials used are generally stainless steel type 302 or 316, or high carbon alloys.

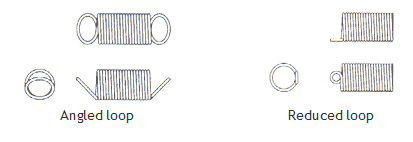

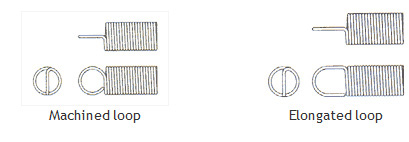

Most extension spring failures occur in the area of the end. To maximize the life of the extension spring, the path of the wire should be smooth and gradual as it flows into the end. Tool marks and other stress concentrations should be held to a minimum. A minimum bend radius of 1 1/2 times the wire diameter is recommended.

We hold an extensive database of spring specifications which can be made to order, but can also produce units to your own specification working from either a brief, technical drawing or by reverse engineering your supplied sample using our ‘In house’ specialist testing equipment, to provide the best advice on design, materials, processes and finishes.

If you have an Extension spring requirement, please contact us to discuss it.

Springcoil Ltd are a Sheffield, UK based Spring Manufacturer and Supplier.